Watcharamongkhol Diecas provides aluminum injection molding services in Nakhon Pathom, Thailand. With over 30 years of experience, our expertise lies in aluminum injection molding, ensuring consistent quality in both the craftsmanship and final product. We prioritize using standardized, certified aluminum alloys to meet our clients’ quality standards. Our injection molding serves primarily automotive, agricultural, and industrial sectors.

Equipped with die casting machines capable of handling up to 125 tons, we have delivered various types of injection-molded products to both domestic and international clients, including automotive parts, motorcycle components, industrial parts, furniture accessories, household equipment, and numerous other metal components.

The process of die casting involves melting metals such as aluminum, magnesium, zinc, and copper into a liquid form through heat. This molten metal is then injected into a mold under high pressure. Subsequently, the piece must cool and solidify before the mold can be opened to extract the finished piece.

Die casting process can be broadly divided into two main types: hot-chamber casting and cold-chamber casting. These processes share many similarities, but cold-chamber casting offers an advantage in terms of the type of metals used, as it can accommodate metals with differing melting points. In contrast, hot-chamber casting is suitable only for metals with lower melting points.

Aluminum injection molding is highly favored in many countries because it is a process capable of producing a large quantity of intricately designed parts continuously. Moreover, aluminum injection molding helps maintain consistent product quality due to its relatively high precision manufacturing. Components manufactured through aluminum molding are both robust and durable against high pressures, yet remain lightweight. This characteristic makes them highly suitable for the automotive industry.

Why customers choose us ?

Quality Control

We are committed to producing consistently high-quality products. With over 30 years of experience in aluminum injection, we have continuously learned, refined, and developed our processes, enabling us to maintain the quality of our production to a level that impresses our customers. We focus not only on the quality of our products but also on delivering great customer service, being honest and transparent from pre-sales to after-sales.

Competitive Pricing

What we consistently prioritize is not only maximizing profit, but fostering long-term relationships with our customers. We never overprice our customers because we want to see them grow sustainably in any industry they are in.

Short Lead Time

Our factory operates with an efficient production process capable of accommodating large quantities. We are stringent on delivery times, ensuring timely shipment of products as per our customers’ set schedules. This commitment is aimed at maintaining consistent service standards for every customer, aiming for their utmost satisfaction.

FAQ

What types of aluminum injection molding do you offer?”

Our factory offers various types of aluminum injection molding for automotive parts, motorcycle components, furniture pieces, industrial parts, and many other metal components. However, we always need to assess the parts before commencing. We analyze the details of the components from drawings, CAD files or sample product.

If there is an existing mold, is it possible to use it for injection?

If the customer already has a mold, we are happy to offer injection services. Customers can send us the details of the component for an initial evaluation, including information such as the material of the part, its weight, and the quantity required. However, if the customer needs a new mold, we are also happy to provide consultation at every stage of the process.

How long does it take to provide a quote?

After receiving all the necessary details about the component, we will evaluate the weight of the part, the materials used, complexity, and the required quantity to provide a quote to the customer. This process generally takes approximately 5-7 business days.

Is there a minimum quantity for production?

Mass production helps control manufacturing costs at a lower point. However, if a customer requires a smaller production quantity, we can accommodate that. The minimum order quantity that we can accept for injection molding ranges from 1,000 to 2,000 pieces.

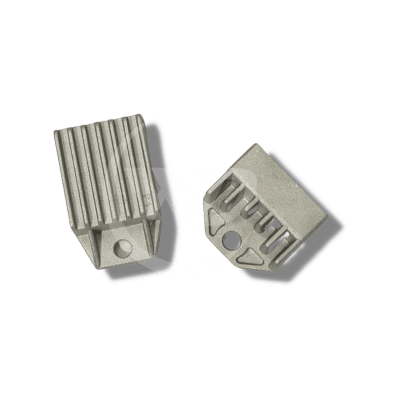

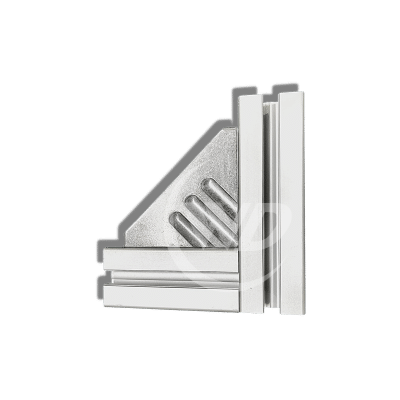

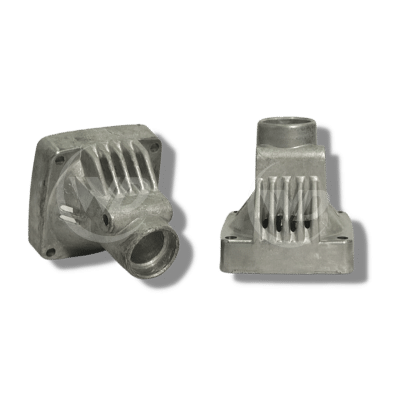

Aluminum injection samples